Sustainability

Sections on this page:

⚓ SAL Reducing the Carbon Footprint

⚓ E-statement of account (E-SA)

From 2011, if you are a listed company, and for all companies from 2013, the European regulations make it compulsory to publish the CO2 emissions generated by the manufacture and transport of your products.

The Company has implemented the following initiatives to substantially reduce the Carbon Footprint of SAL and are as follows:

SAL has saved a lot of trees - we have installed an automated software programme that clears all the account balances down at the end of the month and automatically emails all of our clients.

This process of E-SA that we introduced has saved many reams of paper (the printed statements, the envelopes into which the statements must be placed, the stamps, the glue for the envelope & stamp) as well as the huge saving on the carbon footprint for this process. The carbon footprint has been reduced to virtually zero (because there is no need to use the post office to transport the statements by van, airplane & ship as well as eliminate the need for sorting offices which require heat & light to process the envelopes).

It also improved our cash-flow as companies received the statement of account more quickly than others using the traditional method of using the Post Office and paid us more quickly (this was a side benefit that none of us thought of)!

Through digitally storing data and switching from traditional PCs to Thin Clients.

In 2010 we made the decision to change from our standard desktop PCs to Thin Client terminals.

| Thin client | Thin client With server pro rata +server cooling | PC | |

|---|---|---|---|

| Power consumption | 16W | 41W | 85W |

| x 8 hours per day | 128Wh | 328Wh | 680Wh |

| x 220 working days per year | 28kWh | 72kWh | 149kWh |

| CO2 for 1 workstation per year | 17.64kg | 45.36kg | 93.87kg |

| 10 workstations | 176.4kg | 453.6kg | 938.7kg |

| 100 workstations | 1.76t | 4.54t | 9.39t |

| 1,000 workstations | 17.6t | 45.4t | 93.9t |

| Results based on research by the Fraunhofer Institute. | |||

As well as offering security and IT benefits, this move allowed us to reduce our carbon footprint by 4.36 tonnes and decrease electricity consumption on our staff’s terminals by 51%.

We are continuing to roll out Thin Client terminals throughout our global operations, thus continually reducing our CO2 waste.

By introducing an E-DMS , SAL has been able to substantially reduce the need for storing physical copies of all of the shipping documentation required for each shipment (typically at least 11 to 18 documents per file).

The traditional method of boxing & storing is still a legal requirement (7 years retention) however there is no need to have the file physically retrieved each time a document needs to be reviewed and instead an electronic version is retrieved.

This saves substantial amount in the carbon footprint because hitherto, a van & messenger would be required to travel to the warehouse storing the physical documents, locate the file and bring it to the office and then repeat the process in reverse to place the file back in the warehouse.

We are continuously working to find new ways to reduce our environmental impact and that of our customers:

As part of our commitment to reducing greenhouse gas emissions, SAL is exceeding statutory requirements by forward planning and implementing a wide variety of practical measures. This enables us to support our customers in their drive to meet the required environmental standards.

We strongly believe that it is our responsibility as a forwarding & logistics company to reduce the environmental impact of our activities. This includes actions in two areas.

- We work with our customers to optimise their transport plans and loading.

- At the same time, in partnership with truck manufacturers, we ensure that our vehicles meet with all emission requirements and assess alternative technologies to the diesel engine.

Freight planning

Through maximization of container and vehicle loads and working with customers to optimise our fleet planning (back-hauling)

Fuel economy

Through route planning, minimising mileage and operating a modern fleet of vehicles subjected to constant vehicle checks and maintenance for top fuel efficiency performance

Facility utilisation

Through exploring heating use and implementing best practice to minimize carbon emissions that our facilities generate.

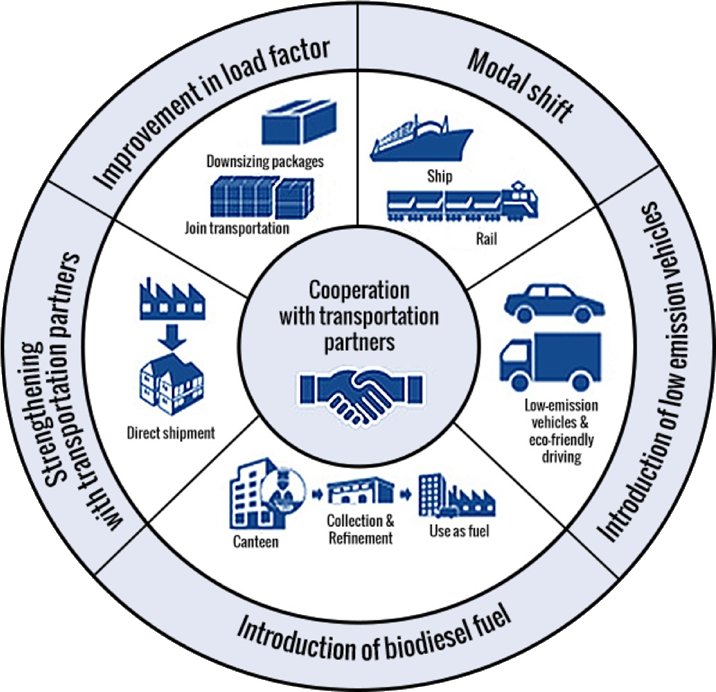

Cooperation with Transport Partners